- Start

- ǀ Produkte

- ǀ Loader wagon

- ǀ ROYAL series

- ǀ without dosing rollers

- ǀ ROYAL 300 K

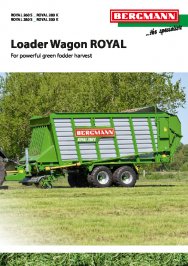

ROYAL 300 K

Tandem chassis, 30 m³ DIN load volume, 2-rotor system, without dosing rollers, from 80 hp

The ROYAL 300 K is a loader wagon with a load volume of 30 m³ and is designed for combined use for green fodder harvest and as forage transport trailer. It has a tandem chassis with parabolic suspension, which provides high driving stability in all conditions. A unique feature of the ROYAL is its 2-rotor system with two synchronously working cutting and press rotors, which are gentle on the crop and save energy. The 1,940 mm wide pick-up with two swath rollers facilitates a clean crop intake. With a cutting unit with 41 knives that achieves a theoretical cut length of 34 mm, the ROYAL is among the loader wagons with the shortest cut. The standard ISOBUS operation offers superior user convenience. The ISOBUS standard allows the use of ISOBUS-compatible operator and tractor terminals.

- Chassis:

- High loads and long service life through torsion-resistant chassis and low dead loader wagon weight

- Easy coupling through hydraulically operated high-lift drawbar for high drawbar

- Narrow drawbar for good manoeuvrability

- Stable when parked through manual folding jack stand

- Bogie:

- High swing angles for good adaptability to terrain, easy driving over silos and easy towing with and handling on the road through tandem chassis with parabolic springs and swing compensation

- Clean mudguards and therefore no soiling of road since mudguards are tapered to the outside

- Manoeuvrability, transport with low ground disturbance also at high payloads and low tyre wear through optional follow-up steering

- High stability in the field and on the silo through 1,900 mm axle track width

- Brake system:

- Safe driving, operational safety and high ease of use through standard dual-circuit air brake system

- PTO shaft:

- Overload protection for tractor and loader wagon through standard wide-angle PTO shaft (on one side) with cam clutch

- Intake:

- Clean fodder collection without loss, also of short fodder, through steered pick-up with 1,940 mm intake width

- Rotor:

- Optimum cut and load rate through 2-rotor system with cutting rotor and press rotor (1,428 mm wide, 600 mm diameter)

- Separation of cutting and pressing action for lower power draw and therefore lower tractor fuel consumption

- No pulping and crushing through perfectly matched operating speed of the two rotors

- Optimized press rotor action through pre-compaction of the crop between cutting and press rotor

- Pre-compacted material fed into the cargo space by the press rotor for optimum utilization of the cargo space and complete filling also with wet and heavy material and at high throughput

- Cutting unit:

- Short cut fodder with a theoretical cut length of 34 mm for good compaction in the silo through 41 knives on one level

- Easy and exact cutting for high fodder quality

- Knife shape and position of rotor tines ensure a pulling cut

- Optimum protection, reliable and smooth retraction of knives into the cutting groove through separate foreign-object protection for each knife

- Tool-less and therefore quick and easy removal of individual knives for maintenance or knife change

- Body:

- The rigid contoured panel body with a front wall that is inclined towards the back and a front section lined with sheet metal plates reliably prevents accumulation of crop deposits

- Good visibility into body during filling and emptying through large viewing window in the front wall

- Durable, impregnated wooden floor

- Reliable mechanical locking of hydraulically operated tailgate also on poor roads

- Scraper floor:

- Long durability and high reserves through four strong round-link steel chains with specially hardened ends

- No chain skipping due to large engagement depth of chain links in the chain sprockets (approx. 95 %)

- No flight skew through paired link elongation

- Reliable crop transport through U-profile flights

- Easy checking of scraper floor and chain tension through automatic chain tensioner

- Readjusting of chain tension at front under the loader wagon in the area of the cutting unit

- Quick emptying through scraper floor that is hydraulically driven on one side

- Even crop feed ensures a good distribution in the silo

- Operation:

- Easy and safe operation allows high daily output

- High ease of use through ISOBUS operation as standard

- High-lift drawbar and knife bar can additionally be operated from the left side (in driving direction) of the loader wagon for easy coupling or maintenance work

- Chassis:

- Hydraulically adjustable high-lift drawbar for high drawbar

- 2 double-acting cylinders

- 40 mm diameter drawbar eye

- Manual folding jack stand

- Bogie:

- 2 rigid braking axles

- Tandem chassis with parabolic suspension and swing compensation

- Axle track width 1,900 mm

- Axle centre distance 1,220 mm

- 8-hole wheel connection

- Angled mudguards

- Brake:

- Dual-circuit air brake system with ALB regulator

- Intake:

- Steered pick-up

- Intake width 1,940 mm

- 5 rows of tines

- 55 mm tine spacing

- Guide comb with 2 swath rollers

- Steered guide wheels with pneumatic tyres

- Rotor:

- 2-rotor system with cutting rotor and press rotor

- 600 mm diameter each

- 1,428 mm wide each

- Cutting unit:

- 41 knives on one level

- Theoretical cut length 34 mm

- Single knife protection mechanism

- Hydraulic knife control

- Tool-less knife change

- Body:

- Rigid body, galvanized and plastic-coated

- Hydraulically operated tailgate

- Impregnated wooden floor, thickness 28 mm

- Visual level indicator via the machine control unit

- Scraper floor:

- Hydraulically driven on one side via spur gearbox

- 4 round-link steel chains (11 x 31 mm each, 15 t breaking load per chain)

- Diameter of feed shaft 40 mm

- Drive:

- Walterscheid wide-angle PTO shaft (on one side) with cam clutch

- PTO speed 1,000 rpm

- Central lubrication system:

- Fully automatic oil lubrication for the rotor and pick-up drive chains

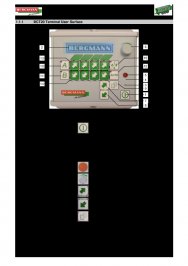

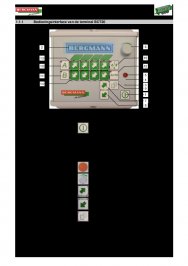

- Operation:

- ISOBUS operation

- Lighting according to German road traffic regulations (StVZO)

- Protective equipment according to German employers’ liability insurance association

| Dimensions | |

|---|---|

| Length | 8.745 mm |

| Width | 2.435 mm |

| Height with body bracket | 3.855 mm |

| Weight | |

| Gross weight | 16.000 kg |

| Gross weight (optional) | 17.000 kg |

| Net weight with basic equipment | 6.040 kg |

| Coupling | |

| High drawbar | x |

| Permissible tongue load of high drawbar | 2.000 kg |

| Drawbar eye Ø 40 mm | x |

| Low drawbar (optional) | x |

| Permissible tongue load of low drawbar (optional) | 3.000 kg |

| Drawbar eye (hitch ring) Ø 50 mm | x |

| Drawbar eye K80 | x |

| Drive | |

| PTO shaft input speed | 1.000 U/min |

| Intake | |

| Intake width of pick-up | 1.940 mm |

| Number of swath rollers | 2 |

| Number of tine rows | 5 |

| Number of double tines per row | 15 |

| Tine spacing | 55 mm |

| Tine diameter | 5 mm |

| Steered pick-up | x |

| Mechanical pick-up drive | x |

| Ground clearance, pick-up | 350 mm |

| Ground clearance of pick-up with extended high-lift drawbar | 600 mm |

| Rotor | |

| Diameter of cutting rotor | 600 mm |

| Diameter of press rotor | 600 mm |

| Width of cutting rotor | 1.428 mm |

| Width of press rotor | 1.428 mm |

| Number of tine rows per cutting rotor | 4 |

| Number of tine rows per press rotor | 2 |

| Cutting unit | |

| Number of knives | 41 |

| Theoretical cut length | 34 mm |

| Body/cargo space | |

| Load | 9.960 - 10.960 kg |

| Load volume according to DIN 11741 | 30 m³ |

| Load volume at medium compaction | 54 m³ |

| Front wall rigid | x |

| Scraper floor | |

| Number of scraper floor chains | 4 |

| Dimensions of links | 11 x 31 mm |

| Max. breaking load per scraper floor chain (total) | 15 (60) t |

| Thickness of wooden floor | 28 mm |

| Hydraulic scraper floor drive | x |

| Scraper floor drive on one side | x |

| Chassis | |

| Tandem chassis | x |

| Parabolic suspension with swing compensation | x |

| Number of rigid axles | 2 |

| Axle track width | 1.900 mm |

| Axle centre distance | 1.220 mm |

| Air brake | x |

| Transport speed | 40 km/h |

| Tyres | |

| 22.5" wheel rim | x |

| Tractor requirements | |

| Engine rating (min. - max.) | 59 - 132/80 - 180 kW/PS |

* We reserve the right to make changes to dimensions, weights and technical data. Dimensions and weights do not necessarily correspond to series versions and are not binding.

Image gallery

×

![]()